2.0 TFSI EA113 upgrade High-pressure pump INTEGRATED

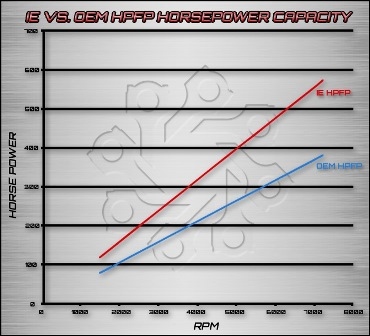

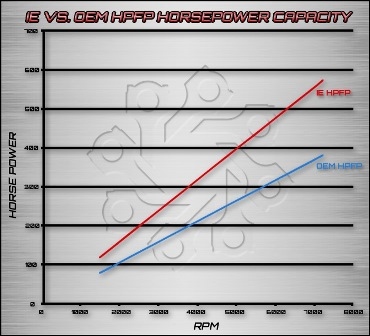

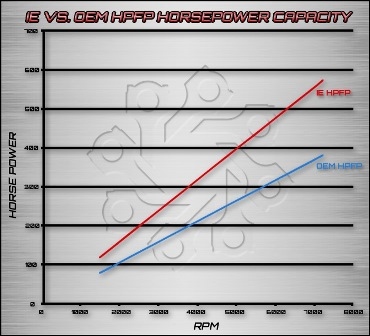

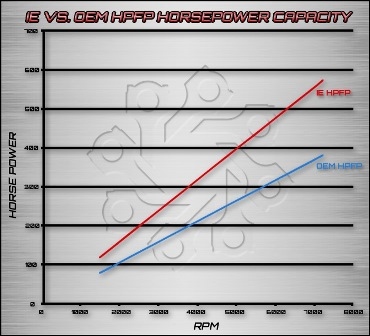

- 50% higher conveying capacity

- no run-in phase necessary

- all pump kits tested before delivery

- high mileage

- Description

- 50 % higher flow rate than the standard pump

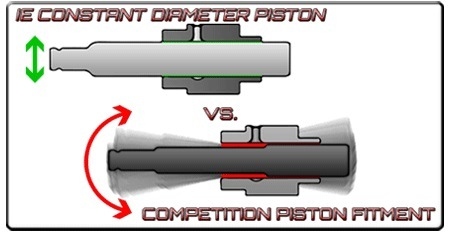

- Continuous piston with special sealing ring

- All pump kits are tested before delivery

- No running-in phase necessary

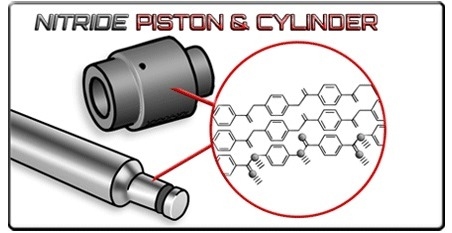

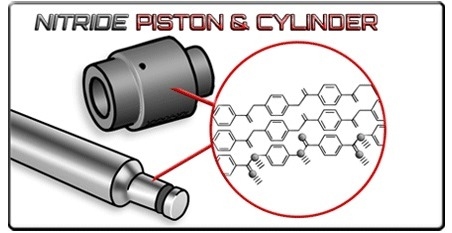

- Piston and cylinder are made of special steel and are also nitrided

- Titanium valve plate and reinforced spring

- Fits for

- Videos

- Questions about the product

- Reviews

- Blog Posts

- Accessories

- Cutsomers also bought

THE ultimate high-pressure pump for all 2.0L TFSI engines from Integrated in the USA.

The advantages at a glance:

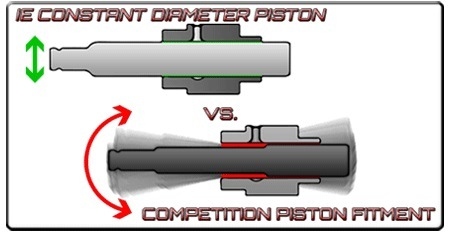

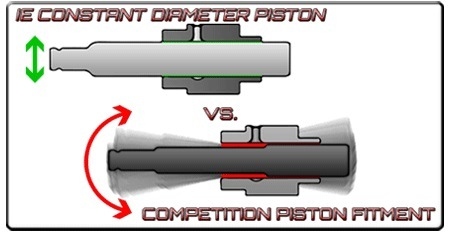

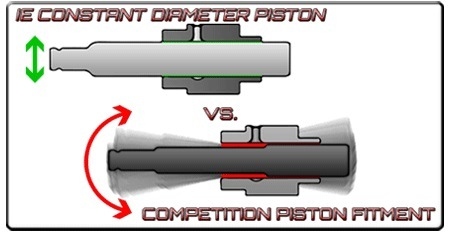

Piston diameter in tune:

Various tests have shown that a constant piston diameter is necessary. Unfortunately, conventional upgrade pumps have the problem that the standard radial shaft seal must continue to be used. The piston then has a step.

However, this step means that the piston loses its guidance. It is similar to a valve in the cylinder head where the valve guide is simply shortened by half. The valve begins to flutter and deflect. In the TFSI high-pressure pump, this gradation also causes increased fuel pressure on the shaft seal. This allows fuel to enter the oil circuit!

The continuous piston from Integrated solves both of these problems. However, this design requires a new oil seal together with the cap.

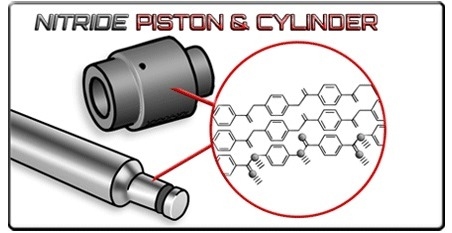

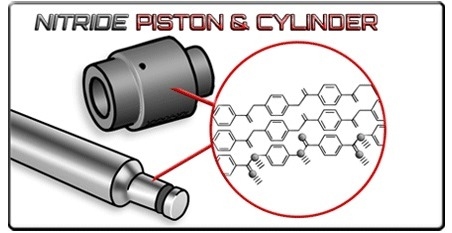

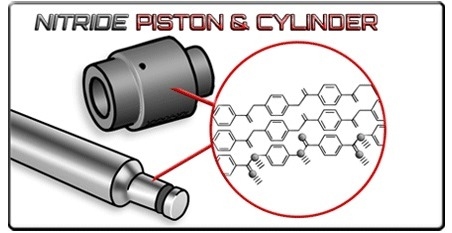

Nitrided piston and cylinder:

The piston and cylinder are already nitrided at the factory. This is done to protect the parts from excessive wear. Nitriding is not a coating, but a process in which nitrogen atoms are applied to the atomic structure of the outer surface of the component. This dramatically increases the surface hardness and wear properties. Integrated has adopted this technology because conventional coatings can cause the layer to flake off. The thickness and exact composition of the nitrate layer has been thoroughly tested in the laboratory and is monitored during each process.

Engine software should be changed to a 9.8 mm pump plunger.

We recommend our matching pump plunger for this.

Manufacturer

Information about the manufacturer

IE - Integrated Engineering

Integrated Engineering

2859 S 1030 W Suite 1 Salt Lake City, UT 84119, United States

sales@performancebyie.com

EU responsible person

BAR-TEK Motorsport GmbH

Im Rauschen Auel 3, 51491 Overath-Brombach, Germany

info@bar-tek.com

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | CDLH | 256 hp (188 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | AXX | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BHZ | 265 hp (195 kW) |

| 2.0 TFSI (EA113) | BPY | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BWA | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | CDLA | 265 hp (195 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | BGB | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BPG | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BUL | 220 hp (162 kW) |

| 2.0 TFSI (EA113) | BWE | 200 hp (147 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | BPJ | 170 hp (125 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | BPY | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BWA | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | CDLB | 272 hp (200 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | ADY | 115 hp (85 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | ATM | 115 hp (85 kW) |

| Engine | Engine code |

|---|

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | BWE | 200 hp (147 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | BWA | 185 hp (136 kW) |

| 2.0 TFSI (EA113) | BWA | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BWJ | 240 hp (177 kW) |

| 2.0 TFSI (EA113) | BWJ | 286 hp (210 kW) |

| 2.0 TFSI (EA113) | BWJ | 310 hp (228 kW) |

| 2.0 TFSI (EA113) | CDLA | 265 hp (195 kW) |

| 2.0 TFSI (EA113) | CDLA | 310 hp (228 kW) |

| 2.0 TFSI (EA113) | CDLD | 240 hp (177 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | BWA | 200 hp (147 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | BWA | 200 hp (147 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | AXX | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BPY | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BWA | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BYD | 230 hp (169 kW) |

| 2.0 TFSI (EA113) | CDL | 240 hp (177 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | CDLF | 270 hp (199 kW) |

| 2.0 TFSI (EA113) | CDLG | 235 hp (173 kW) |

| 2.0 TFSI (EA113) | CRZA | 256 hp (188 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | AXX | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BWA | 200 hp (147 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | CDLJ | 220 hp (162 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | CDLA | 265 hp (195 kW) |

| 2.0 TFSI (EA113) | CDLK | 280 hp (206 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | ADY | 115 hp (85 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | ATM | 115 hp (85 kW) |

Accessories

Cutsomers also bought

THE ultimate high-pressure pump for all 2.0L TFSI engines from Integrated in the USA.

The advantages at a glance:

- 50 % higher flow rate than the standard pump

- Continuous piston with special sealing ring

- All pump kits are tested before delivery

- No running-in phase necessary

- Piston and cylinder are made of special steel and are also nitrided

- Titanium valve plate and reinforced spring

Piston diameter in tune:

Various tests have shown that a constant piston diameter is necessary. Unfortunately, conventional upgrade pumps have the problem that the standard radial shaft seal must continue to be used. The piston then has a step.

However, this step means that the piston loses its guidance. It is similar to a valve in the cylinder head where the valve guide is simply shortened by half. The valve begins to flutter and deflect. In the TFSI high-pressure pump, this gradation also causes increased fuel pressure on the shaft seal. This allows fuel to enter the oil circuit!

The continuous piston from Integrated solves both of these problems. However, this design requires a new oil seal together with the cap.

Nitrided piston and cylinder:

The piston and cylinder are already nitrided at the factory. This is done to protect the parts from excessive wear. Nitriding is not a coating, but a process in which nitrogen atoms are applied to the atomic structure of the outer surface of the component. This dramatically increases the surface hardness and wear properties. Integrated has adopted this technology because conventional coatings can cause the layer to flake off. The thickness and exact composition of the nitrate layer has been thoroughly tested in the laboratory and is monitored during each process.

Engine software should be changed to a 9.8 mm pump plunger.

We recommend our matching pump plunger for this.

Manufacturer

Information about the manufacturer

IE - Integrated Engineering

Integrated Engineering

2859 S 1030 W Suite 1 Salt Lake City, UT 84119, United States

sales@performancebyie.com

EU responsible person

BAR-TEK Motorsport GmbH

Im Rauschen Auel 3, 51491 Overath-Brombach, Germany

info@bar-tek.com

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | CDLH | 256 hp (188 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | AXX | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BHZ | 265 hp (195 kW) |

| 2.0 TFSI (EA113) | BPY | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BWA | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | CDLA | 265 hp (195 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | BGB | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BPG | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BUL | 220 hp (162 kW) |

| 2.0 TFSI (EA113) | BWE | 200 hp (147 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | BPJ | 170 hp (125 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | BPY | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BWA | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | CDLB | 272 hp (200 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | ADY | 115 hp (85 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | ATM | 115 hp (85 kW) |

| Engine | Engine code |

|---|

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | BWE | 200 hp (147 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | BWA | 185 hp (136 kW) |

| 2.0 TFSI (EA113) | BWA | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BWJ | 240 hp (177 kW) |

| 2.0 TFSI (EA113) | BWJ | 286 hp (210 kW) |

| 2.0 TFSI (EA113) | BWJ | 310 hp (228 kW) |

| 2.0 TFSI (EA113) | CDLA | 265 hp (195 kW) |

| 2.0 TFSI (EA113) | CDLA | 310 hp (228 kW) |

| 2.0 TFSI (EA113) | CDLD | 240 hp (177 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | BWA | 200 hp (147 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | BWA | 200 hp (147 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | AXX | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BPY | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BWA | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BYD | 230 hp (169 kW) |

| 2.0 TFSI (EA113) | CDL | 240 hp (177 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | CDLF | 270 hp (199 kW) |

| 2.0 TFSI (EA113) | CDLG | 235 hp (173 kW) |

| 2.0 TFSI (EA113) | CRZA | 256 hp (188 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | AXX | 200 hp (147 kW) |

| 2.0 TFSI (EA113) | BWA | 200 hp (147 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | CDLJ | 220 hp (162 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | CDLA | 265 hp (195 kW) |

| 2.0 TFSI (EA113) | CDLK | 280 hp (206 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | ADY | 115 hp (85 kW) |

| Engine | Engine code |

|---|---|

| 2.0 TFSI (EA113) | ATM | 115 hp (85 kW) |

Accessories

Cutsomers also bought