Pistons - Small and extremely important for your engine

As motorsport professionals, we talk about pistons all the time. That's because the piston is an extremely important component for any engine.

Especially when it comes to performance enhancement, we depend on the quality of these capped hollow cylinders. Here, this relatively small component has to withstand a lot. What pistons are for, how they work and what makes them so important for tuning, you can find here.

What are pistons used for?

The pistons are part of the combustion chamber of your engine and seal it off on the top with the piston rings. Pistons are there to transfer pressure to the crankshaft and thus convert the force into a rotation movement.

During the combustion process, the air-fuel mixture is compressed by the constant up-and-down motion of the pistons and ignited by the spark plugs. This small explosion causes lots of pressure and heat, pushing the pistons down again. There is a lot of heat at play here, and the load on the components is therefore extremely high. We are talking about a maximum pressure of 180 bar and a combustion temperature of 2,000 °C. The pistons themselves hit 350 °C, which the components have to permanently withstand.

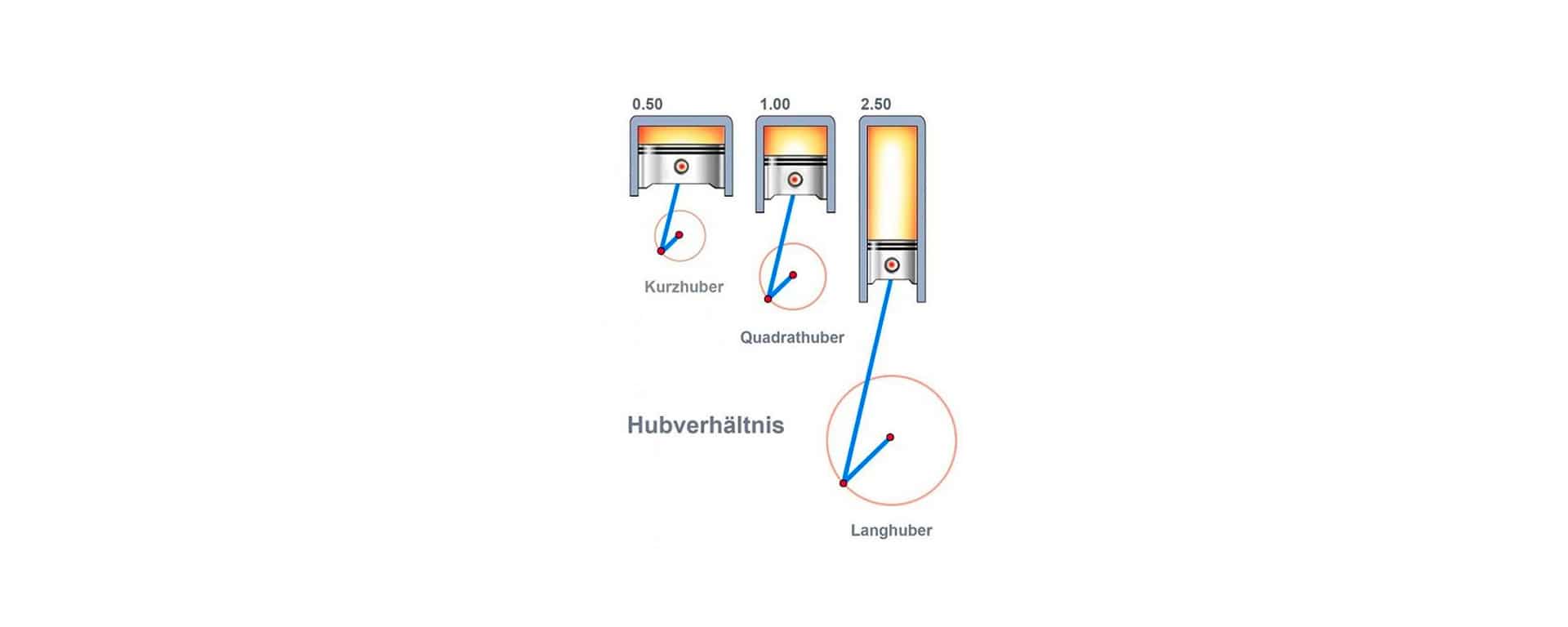

The pistons convert the energy produced by combustion into mechanical motion and the vertical movement into a rotation movement. This happens because the pistons are connected to the crankshaft via the connecting rods. The connecting rods are at an angle in most positions, meaning that not the entire pressure can be passed on and a lateral force also occurs, which acts on the pistons. Imagine how everything pulls and presses on the piston. During the combustion process, the speed of the pistons constantly changes, resulting in additional strain.

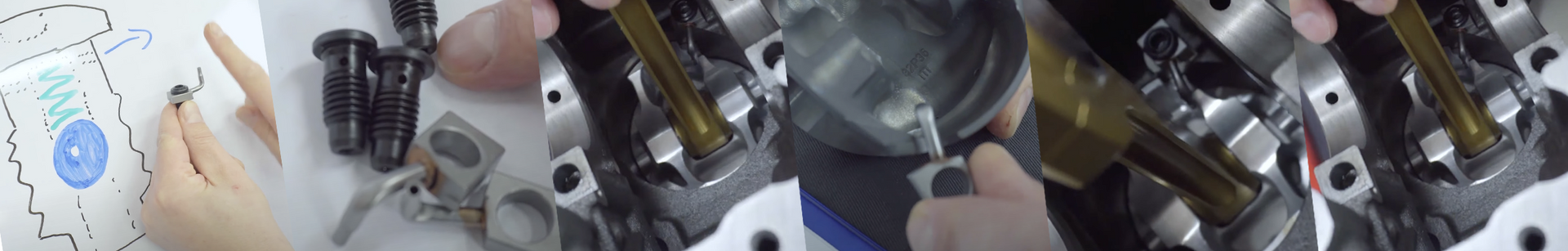

Pistons also seal the engine from exhaust gases. The piston rings take on this task. They reduce the blow-by gases that try to ‘slip by’ the pistons. They also ensure sufficient lubrication of the cylinder walls. The correct installation of the piston rings is very important in order to protect the engine from piston seizures and prevent drops in power. We have thus also put together extensive instructions for installing piston rings for you.

How is a piston structured?

The structure of a piston is simple. A piston is a hollow cylinder with a ‘cover’. It consists of the:

- piston head,

- piston crown (fire land)

- piston rings,

- piston pin, and

- piston skirt.

The piston head is the upper part of the piston. It distributes the energy produced by combustion to the other areas of the piston and on down to the crankshaft. The piston beam is the lower area of the piston and guides the component within the cylinder. Although the beam needs to be extremely strong in order not to get damaged under the heavy load, it must also be able to react flexibly to the deformation of the cylinder.

The most important area of the piston is the ring zone. At least two rings are installed here: at the top is the compression ring and at the bottom the oil control ring. On this page, you will see how to correctly mount the rings.

Pistons in combustion engines: these are the differences

Pistons must also be optimised for different combustion processes in different engines. In particular, pistons for diesel engines differ from those for petrol engines. However, there is also a difference between pistons for naturally aspirated engines and pistons for turbocharged engines.

Pistons for diesel engines

Diesel pistons have it harder: for them, the thermal load is much higher than with petrol engines. For this reason, the piston rings and piston ring grooves are reinforced. This can be achieved, for example, by adding brass bushings in the pin hole. With diesel engines, the piston head is also frequently sprayed with oil. A circumferential oil channel is also often used.

Pistons for petrol engines

Pistons for petrol engine can manage higher speeds with a significantly lower wall thickness. Here, you will also find recesses in the head that accommodate the valves in the combustion chamber. The piston beam is usually coated in order to be able to slide through the cylinder better.

Piston tuning – how can you boost performance with pistons?

Pistons play an important role in tuning, as they are the heart of your engine. For this purpose, the piston beam is especially often optimised: the wider this is, the better it can handle the enormous shear forces. At the same time, high-quality alloys and high-strength material ensure that the tuning pistons are also very lightweight and stable. The piston rings are also optimised for the performance boost: the compression ring consists of gas-nitrided steel and the oil control ring is hook-shaped and elastic. This combination is unbeatable because it improves essential tuning factors: oil monitoring, ring tension, friction, adjustment, and sealing.

Piston care & maintenance – what must be observed?

Make sure to only use fuel with the correct octane rating. This way, you protect your pistons and help allow them to do their job reliably and for a long time. You should also regularly check your spark plugs and replace them if necessary. The same applies to your engine oil: Use suitable, high-quality oil. In general, you should regularly keep an eye on the oil level and oil pressure and, if necessary, also replace the oil pump, oil filter, etc.

If you need the right piston, ask BAR-TEK®

We will find the right pistons for your engine and your desired performance. Even the famous, German TV show host J.P. Krämer says so. Just give us a call or e-mail us and get advice from professionals.

You want to know more about piston rings, piston coating etc.?

Here you will find everything you need to know: