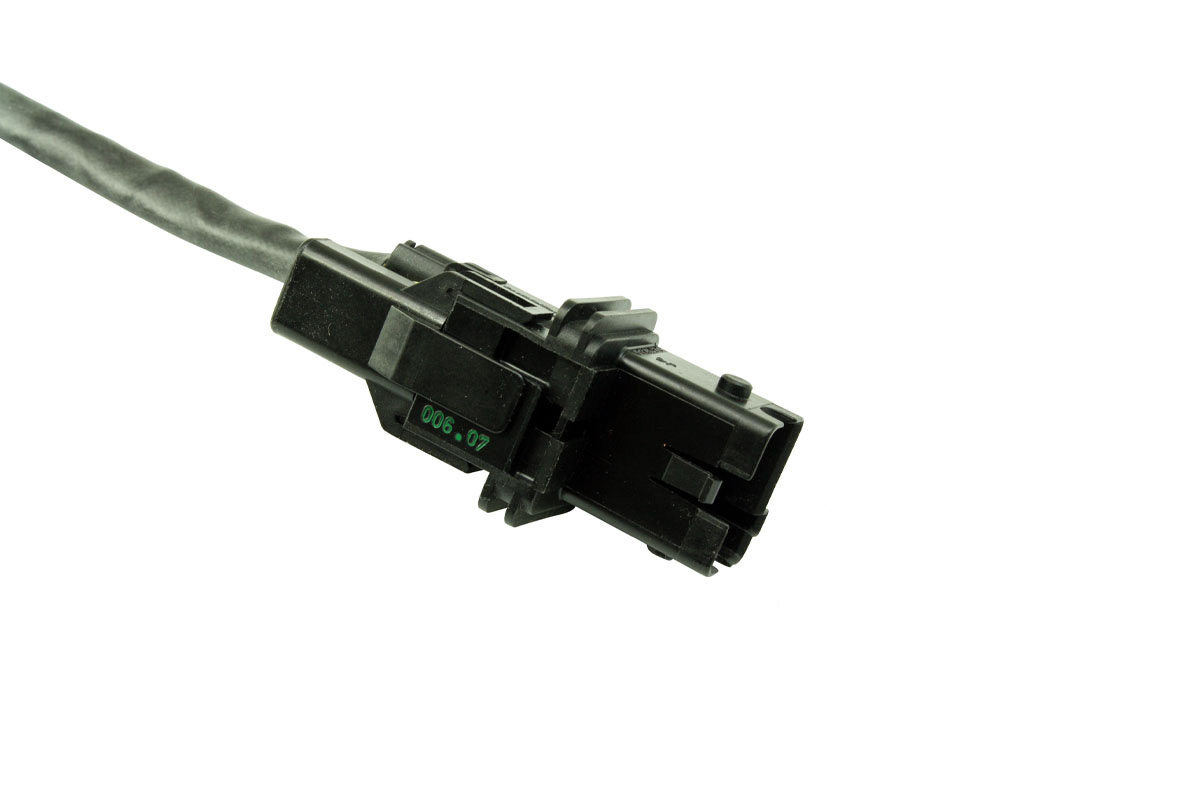

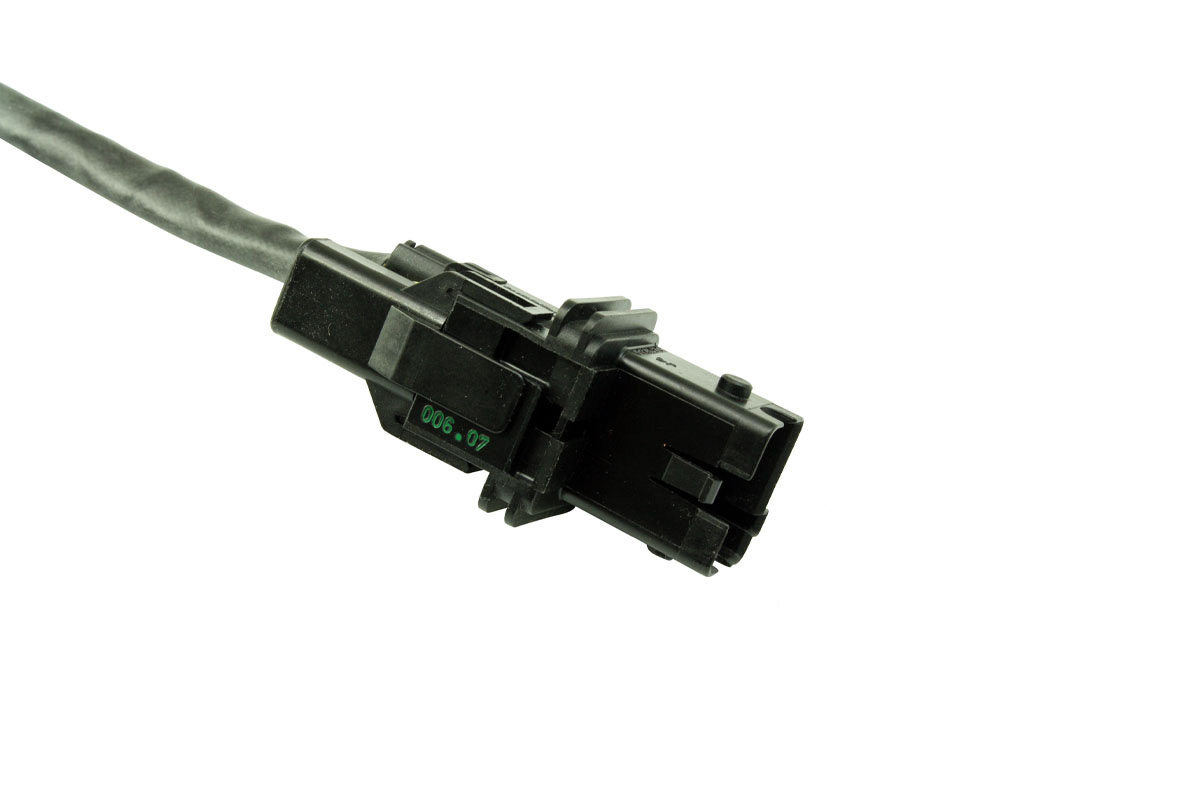

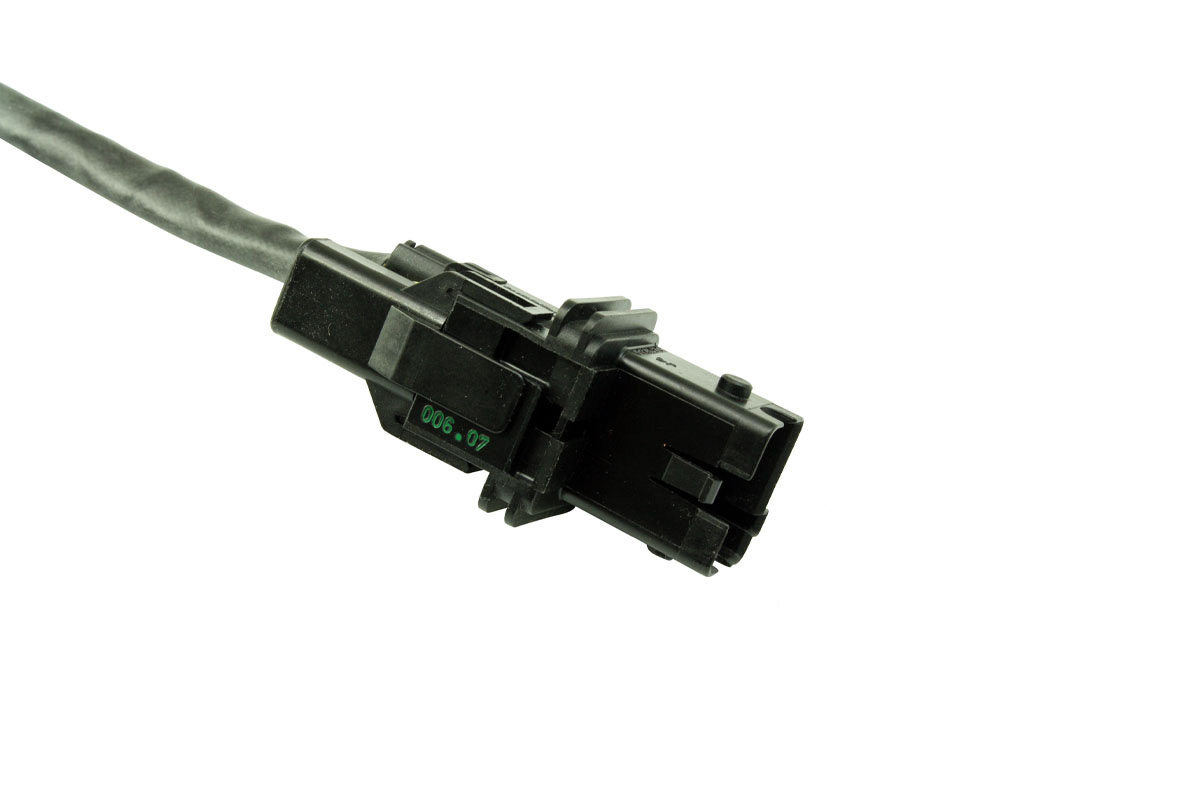

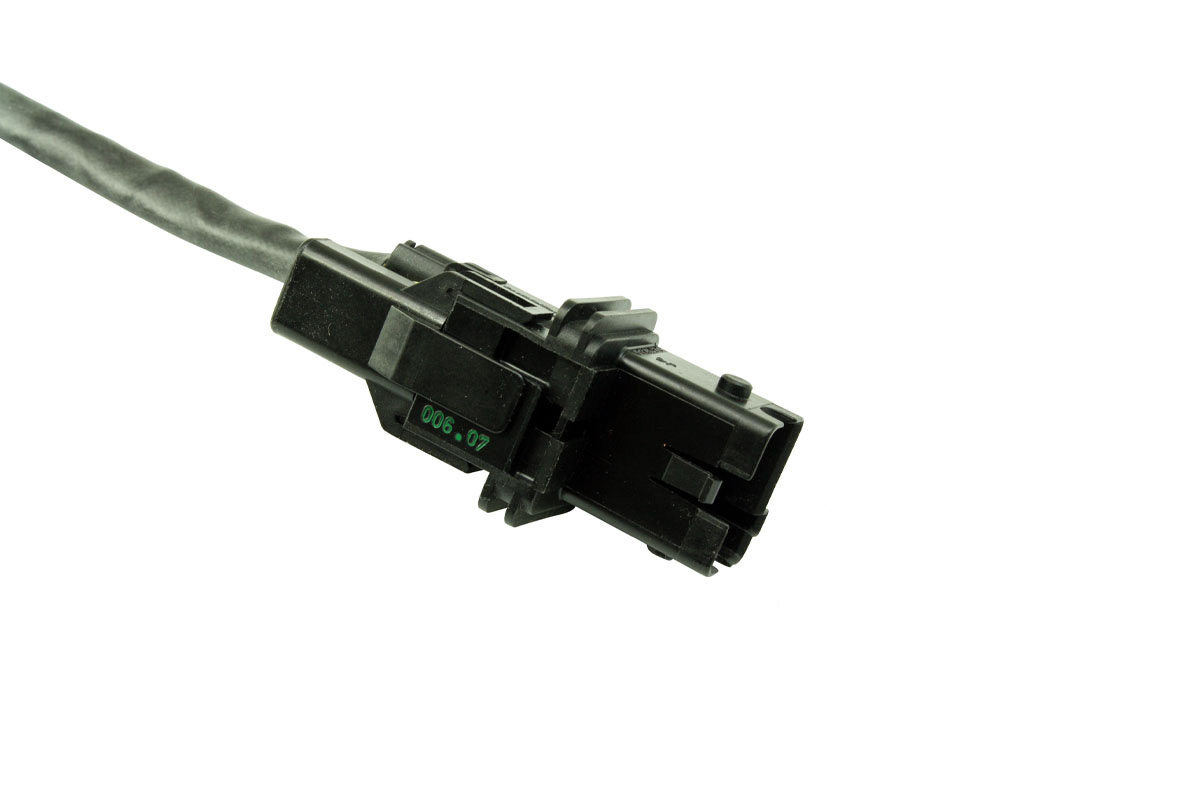

Wideband O2 lambda sensor LSU 42 UEGO Bosch with threaded socket AEM

- Tightening torque: 40 - 60 Nm

- HIGH-BOOST

- Description

- Kit with probe and stainless steel threaded weld-in socket

- Installation in flue gas pipes at a point with a representative flue gas composition, in compliance with the prescribed temperature limits.

- The probe ceramic heats up quickly after the probe heater is switched on. After the ceramic has heated up, the occurrence of condensation, which could damage the hot probe ceramic, must be ruled out.

- The installation angle should be as vertical as possible, but at least 10° from the horizontal. This prevents liquid from collecting between the probe housing and the sensor element. An inclination of 90 ° to the exhaust gas flow should be aimed for, but not more than 90 ° + 15 ° gas inlet opening against the exhaust gas flow) or 90 ° - 30 °. Other angular positions may have to be assessed separately.

- Tightening torque: 40 - 60 Nm

- Fits for

- Videos

- Questions about the product

- Reviews

- Blog Posts

- Accessories

AEM wideband O2 lambda sensor LSU 42 UEGO Bosch with threaded socket

Lambda sensor with Bosch 4.2 LSU wideband UEGO O2 sensor incl. threaded socket

Included in the scope of delivery:

The LSU broadband lambda probe is a planar two-cell ZrO2 limit current probe with integrated heater. It is suitable for measuring the oxygen content and the λ value of exhaust gases in vehicle engines. Due to its continuous characteristic curve in the range from λ = 0.65 to air, it can be used universally for λ = 1 as well as for other λ ranges.

Accessories

AEM wideband O2 lambda sensor LSU 42 UEGO Bosch with threaded socket

Lambda sensor with Bosch 4.2 LSU wideband UEGO O2 sensor incl. threaded socket

Included in the scope of delivery:

- Kit with probe and stainless steel threaded weld-in socket

The LSU broadband lambda probe is a planar two-cell ZrO2 limit current probe with integrated heater. It is suitable for measuring the oxygen content and the λ value of exhaust gases in vehicle engines. Due to its continuous characteristic curve in the range from λ = 0.65 to air, it can be used universally for λ = 1 as well as for other λ ranges.

- Installation in flue gas pipes at a point with a representative flue gas composition, in compliance with the prescribed temperature limits.

- The probe ceramic heats up quickly after the probe heater is switched on. After the ceramic has heated up, the occurrence of condensation, which could damage the hot probe ceramic, must be ruled out.

- The installation angle should be as vertical as possible, but at least 10° from the horizontal. This prevents liquid from collecting between the probe housing and the sensor element. An inclination of 90 ° to the exhaust gas flow should be aimed for, but not more than 90 ° + 15 ° gas inlet opening against the exhaust gas flow) or 90 ° - 30 °. Other angular positions may have to be assessed separately.

- Tightening torque: 40 - 60 Nm

Accessories